Crowcon diseñó una solución a medida para una consultoría de ingeniería global que combinaba un sistema de muestreo a medida, con detección puntual y un sistema de control con clasificación de nivel de integridad de seguridad (SIL), para garantizar una supervisión fiable de los gases en este difícil emplazamiento.

La necesidad - Requisitos

El cliente, un fabricante y consultor mundial de ingeniería, tenía unas nuevas instalaciones para la investigación y el desarrollo (I+D) de motores y necesitaba controlar el hidrógeno in situ. Sin embargo, no era una tarea sencilla: debido a la naturaleza de su trabajo, el emplazamiento presentaba diversos entornos, incluidos conductos de alta velocidad con flujos turbulentos y corrientes de gas a alta temperatura, que eran muy difíciles de supervisar y quedaban fuera del alcance de las opciones "estándar". El equipo EFS de Crowcon resolvió el problema diseñando una solución personalizada que combinaba un sistema de muestreo a medida con detección puntual y un sistema de control clasificado según el nivel de integridad de la seguridad (SIL), para garantizar una supervisión fiable de los gases en este difícil emplazamiento.

Conversaciones con el cliente

Al equipo de EFS le gusta trabajar estrechamente con cada cliente para asegurarse de que se comprenden todas las necesidades, factores y preferencias, y ese enfoque dio sus frutos en este caso. La comunicación se mantuvo en todo momento, desde el estudio inicial hasta la construcción final, mediante una combinación de visitas a las instalaciones, reuniones de equipo y charlas continuas. "Esto nos permitió entender no sólo qué

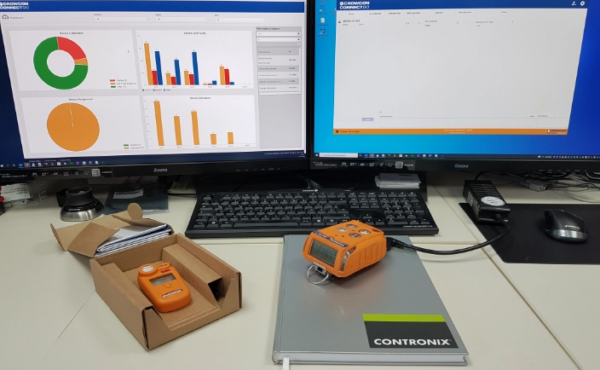

necesitaba el cliente, sino también con qué estaba familiarizado y qué prefería", explica Jackie Marsh, ingeniera de desarrollo comercial del equipo de EFS. "En este caso, por ejemplo, incorporamos un sistema de control con clasificación SIL a nuestra solución personalizada, porque el cliente estaba familiarizado con él".

Los retos de controlar los niveles de gas en flujos turbulentos y a altas temperaturas eran el núcleo de este proyecto. "Jackie Marsh, ingeniera de desarrollo empresarial del equipo de EFS, explica: "Contratamos a algunos especialistas para abordar los retos técnicos, lo que nos permitió conocer a fondo los problemas y nos aportó experiencia.

El equipo de EFS diseñó un sistema de muestreo personalizado que podía controlar el hidrógeno en todas las zonas donde las condiciones eran muy difíciles. Este enfoque de muestreo se combinó con el uso de detectores puntuales en las partes menos difíciles del emplazamiento, y un sistema de control que aunaba ambos, para ofrecer una solución de amplio alcance adecuada para todas las zonas.

El nuevo sistema se integra perfectamente con el resto de sistemas de seguridad del cliente, proporcionando una garantía insuperable. A pesar de las dificultades, el equipo de EFS está orgulloso del resultado y espera poder aplicar la experiencia adquirida en este proyecto en otras instalaciones similares.

Si sus instalaciones se beneficiarían de una supervisión de gases personalizada, ¿por qué no se pone en contacto con nosotros? Nos pondremos en contacto con usted para charlar sobre sus necesidades y las posibles soluciones.

Descargar estudio de caso en PDF

Póngase en contacto con nosotros hoy mismo con sus requisitos para ver cómo podemos ayudarle.

VISIÓN DEL SECTOR

Suscríbase para recibir las últimas novedades de

en su buzón de entrada.

Información sobre Crowcon Privacidad y Política de cookies. Si cambia de opinión, puede darse de baja en cualquier momento