Eine wirksame und präzise Gasdetektion für Wasserstoff ist von entscheidender Bedeutung. Dieses geruchlose Gas ist hochentzündlich, was in Kombination mit seiner unsichtbaren Flamme die frühzeitige Erkennung von Lecks zu einem entscheidenden Faktor für die Sicherheit der Menschen in seiner Umgebung macht. Crowcon war in der Lage, einem führenden Wasserstoffbetankungsunternehmen modernste Wasserstoffdetektionstechnologie zur Verfügung zu stellen, um das Personal und die Kunden zu schützen und eine sicherere, umweltfreundlichere Zukunft für alle zu schaffen...

Das Unternehmen ist führend bei der Entwicklung modernster Produkte für die Wasserstoffbetankung und beschleunigt den Wasserstofftransport und die Mobilität in Großbritannien und Europa. Mit ihrer bahnbrechenden Wasserstofftankstelle (Hydrogen Refuelling Station, HRS) bietet diese mobile, in sich geschlossene Betankungslösung eine kostengünstige Möglichkeit, Wasserstoff in Transportqualität schnell und effizient direkt an den Einsatzort in Fahrzeugen zu liefern. Um die Sicherheit der HRS zu gewährleisten, war jedoch ein erstklassiges Wasserstoff-Detektionssystem erforderlich. An dieser Stelle kam Crowcon ins Spiel.

Der Bedarf an erhöhter Sicherheit bei der Wasserstoffabgabe

Wasserstofflecks bergen ihre eigenen Risiken. Mit einem Entflammbarkeitsbereich, der bei einer Konzentration von nur 4 % in der Luft beginnt, ist die Gefahr von Bränden und Explosionen in der Nähe von Wasserstoff sehr groß, insbesondere in Gegenwart von Zündquellen. Da Wasserstoff leichter als Luft ist, kann er in geschlossenen Räumen den Sauerstoff verdrängen, was zu einem Erstickungsrisiko führen kann. Es ist äußerst wichtig, Lecks so schnell wie möglich zu erkennen, bevor sie ein gefährliches Ausmaß erreichen können.

"Sicherheit steht bei allem, was wir tun, im Mittelpunkt, und natürlich ist die Lecksuche ein wichtiger Bestandteil davon. Wasserstoff ist eine ziemlich undichte Angelegenheit. Deshalb wollen wir natürlich sicherstellen, dass wir im Falle eines Lecks sehr schnell reagieren können, und zwar sowohl auf der Seite unserer Anlagen als auch auf der Seite der Anlagen anderer, mit denen wir in Berührung kommen", so der Marketing- und Vertriebsleiter.

Die unsichtbare Flamme von Wasserstoff erschwert die visuelle Erkennung von Bränden, was die Explosionsgefahr erhöht und die Bedeutung zuverlässiger Erkennungssysteme unterstreicht, um Lecks so früh wie möglich zu erkennen und zu stoppen. Durch die Nutzung der besonderen molekularen Eigenschaften von Wasserstoff kann das Molecular Property SpectrometerTM (MPSTM) von Crowcon das Vorhandensein des Gases schnell erkennen, bevor es gefährliche Werte erreicht. Diese Fähigkeit zur Früherkennung ist entscheidend dafür, dass das Team in der Lage ist, Wasserstofflecks aufzuspüren, "lange bevor wir in die Nähe der gefährlichen Grenze kommen", erklärt der Marketing- und Vertriebsleiter des Unternehmens, so dass die Mitarbeiter in der Lage sind, vorbeugende Maßnahmen zu ergreifen und das Schlimmste zu verhindern.

Die Lösung von Crowcon

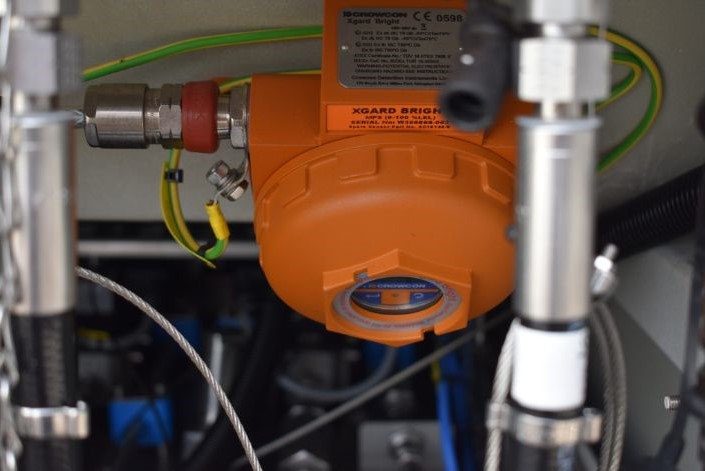

Die rasche Ausbreitung des Gases in die Atmosphäre macht die Erkennung von Wasserstofflecks zu einer Herausforderung - aber nicht für Crowcon, dank seiner bahnbrechenden Xgard Bright mit MPSTM-Technologie:

Über MPSTM Technologie

- Der MPSTM-Sensor(Molecular Property SpectrometerTM ) detektiert und identifiziert über 15 verschiedene brennbare Gase automatisch und in Echtzeit.

- Der MPSTM-Sensor ist für die Wasserstoffdetektion maßgeschneidert, widersteht Verunreinigungen und verhindert eine Vergiftung des Sensors.

- Es werden nur zwei MPSTM-Geräte benötigt, was dazu beiträgt, Platz zu sparen, ohne die Sicherheit zu beeinträchtigen.

- Eine Kalibrierung ist nicht erforderlich, wodurch die Interaktion mit dem Detektor reduziert wird, was zu niedrigeren Gesamtbetriebskosten über den Lebenszyklus des Sensors führt.

- Durch Selbstüberwachungs- und automatische Meldefunktionen ist eine planmäßige Wartung nicht mehr erforderlich.

Crowcons Xgard Bright mit MPSTM-Sensor wurde speziell für die Erkennung von Wasserstoff entwickelt. Durch die Integration mit dem HRS des Unternehmens haben wir die Sicherheit vor Ort verbessert und gleichzeitig die Notwendigkeit einer planmäßigen Wartung beseitigt, die Effizienz erhöht und die Kosten durch Selbstüberwachung gesenkt. Ohne den Betrieb zu unterbrechen, meldet der MPSTM-Sensor automatisch alle Probleme, was sowohl Zeit spart als auch dem Team Sicherheit verschafft.

Diese automatisierten Sicherheitsfunktionen sind für das HRS von entscheidender Bedeutung, da es an andere Unternehmen verteilt wird und daher nicht immer vom Team bedient werden kann. Hier hat sich die MPSTM-Technologie von Crowcon als unschätzbar wertvoll erwiesen: durch die automatische Erkennung von Lecks. Wird ein Leck oder eine Störung festgestellt, werden die Ventile geschlossen und die Sicherheit bis zum Eintreffen eines Technikers gewährleistet, um die Sicherheit unserer Kunden, unseres Eigentums und unseres Personals zu gewährleisten. "Wir verlassen uns darauf, dass das System jedes Wasserstoffleck erkennt. Und wir vertrauen darauf, dass es das tut", erklärt der Kontrollingenieur des Unternehmens.

Kompakte und effiziente Alarmierung

Umfassende Sicherheitsmaßnahmen und fortschrittliche Überwachungstechnologien sind für den sicheren Umgang mit Wasserstoff unerlässlich, aber auch wirksame Alarmsysteme, die das Personal vor Gefahren warnen, sind von entscheidender Bedeutung. Die Alarmtafel von Crowcon Gasmaster 4-Alarmzentrale von Crowcon, die nahtlos in den ausgewählten Detektor integriert ist, erfüllt nicht nur die wesentlichen Alarmanforderungen des Unternehmens, sondern ist auch in Bezug auf die Größe bemerkenswert effizient. Ihr schlankes Design macht sie zur idealen Wahl, um die Sicherheit zu erhöhen und gleichzeitig die besondere Effizienz zu maximieren.

Sollte während des Betankungsvorgangs etwas mit einem der Schläuche oder einem der Geräte in der Anlage schiefgehen, warnt das System die Mitarbeiter optisch und akustisch, damit sie sich entfernen können. Wenn ein Leck entdeckt wird, werden die Ventile automatisch geschlossen, um zu verhindern, dass Wasserstoff in die Anlage eindringt oder aus ihr austritt, so dass das Team volles Vertrauen in die Sicherheit seines Personals und seiner Kunden hat.

Aufbau starker Partnerschaften für eine sicherere Zukunft

Dank Crowcon hat das Team:

- die mit der Lagerung und dem Transport von Wasserstoff verbundenen erheblichen Gefahren zu minimieren und die Sicherheit des Personals, der Kunden und der Kunden des Unternehmens zu gewährleisten

- Er war führend bei der Einführung eines neuen Sicherheitsstandards im Wasserstofftransport.

- Beschleunigte die Nutzung von Wasserstoff im Verkehrswesen in Großbritannien und Europa.

- Erleichterung des Übergangs zu Netto-Null-Emissionen und Schaffung einer nachhaltigeren Zukunft für alle.

Unser technisches Team ist sich der Sicherheitsrisiken bewusst, die bei der Arbeit mit Wasserstoff auftreten können, und weiß, wie wichtig es ist, über ein zuverlässiges Gaswarnsystem zu verfügen. Wenn Sie weitere Informationen wünschen, mehr darüber erfahren möchten, wie wir Ihre Wasserstoffinfrastruktur schützen können, oder mit einem Wasserstoffexperten sprechen möchten, wenden Sie sich an unser Team.

Verwandte FALLSTUDIEN

Melden Sie sich an, um die neuesten Erkenntnisse zu erhalten

IN Ihrem Posteingang

Lesen Sie über Crowcon's Datenschutz und Cookie-Richtlinie hier. Wenn Sie Ihre Meinung ändern, können Sie sich jederzeit abmelden