Die Raffinerie in Singapur ist seit über 50 Jahren in Betrieb und rühmt sich, die größte Raffinerie in

Südostasien zu sein. Mit zwei erstklassigen Produktionsanlagen im Offshore-Bereich von Singapur ist diese Raffinerie ein wichtiger Akteur im Energie- und Petrochemiesektor. Die Anlage in Singapur produziert Kraftstoffe für den Einzelhandel, Schmierstoffe, Luftfahrt, Marine und Bitumen.

Diese Großraffinerie setzt seit über 10 Jahren auf Gaswarnlösungen von Crowcon. Von Personenmonitoren bis hin zu Festpunktdetektoren bietet Crowcon einen umfassenden Wartungs- und Kalibrierungsservice, der sicherstellt, dass alle vor Ort eingesetzten Geräte den Gesundheits-, Sicherheits- und Umweltverfahren des Standorts entsprechen.

Die Raffinerie birgt viele Gefahren, darunter brennbare Gase, Schwefelwasserstoff (H2S) und Fluorwasserstoff (HF). Als Teil des Raffinationsprozesses wird Fluorwasserstoff (HF) als Alkylierungskatalysator zur Herstellung von hochoktanigem Benzin verwendet.

Fluorwasserstoff und Flusssäure sind sehr ätzend und müssen in Übereinstimmung mit geeigneten Risikomanagementverfahren gehandhabt werden. In den Verordnungen über Sicherheit und Gesundheitsschutz am Arbeitsplatz (Allgemeine Bestimmungen) sind Leitlinien und zulässige Expositionsgrenzwerte für Arbeitnehmer in Industrien und Einrichtungen festgelegt, in denen Fluorwasserstoffsubstanzen verwendet werden.

Der PEL-Wert (zulässiger Expositionsgrenzwert) für WSH liegt bei 3 Teilen pro Million (ppm), gemittelt über eine achtstündige Arbeitsschicht. Darüber hinaus müssen alle Mitarbeiter, die in einer HF-Anlage arbeiten, einen chemikalienbeständigen Anzug mit vollständigem Gesichtsschutz tragen. Auch Neoprenhandschuhe müssen vor der Benutzung auf Dichtheit geprüft werden. Beim Verlassen der HF-Anlage muss die gesamte persönliche Schutzausrüstung in einem Laugenbad dekontaminiert werden. Jede Arbeit in einer HF-Anlage ist also mit einem hohen Aufwand und wichtigen Schutzmaßnahmen verbunden

Die Anforderung

In der HF-Anlage der Raffinerie wird konzentrierte HF-Säure (98 %) verarbeitet, und jede Leckage über 3 ppm löst einen Anlagenalarm aus, woraufhin alle Arbeiter in der Anlage evakuiert werden. Bei einer Anlage mit Hunderten von Mitarbeitern vor Ort und einer Rohdestillationsproduktion von durchschnittlich 500 Fässern pro Tag könnte jede Anordnung zur Arbeitseinstellung oder Evakuierung Verluste in Millionenhöhe verursachen.

Jeder Vorfall, bei dem ein HF-Detektor in den Alarmmodus geht, muss untersucht und ein vollständiger Bericht zur Überprüfung durch die Geschäftsleitung vorgelegt werden. Daher ist es wichtig, dass Gasdetektoren für HF niedrige ppm HF mit minimalen Fehlalarmen erkennen können.

Angesichts des kritischen Charakters der HF-Detektion verlangen die Benutzer auch monatliche Bump-Tests und eine vierteljährliche Kalibrierung der Gasdetektoren. Dies ist keine Kleinigkeit, da in der HF-Anlage mehr als 40 HF-Detektoren installiert sind, von denen einige das Sensorelement über vier Stockwerke verteilt haben.

Der Ansatz

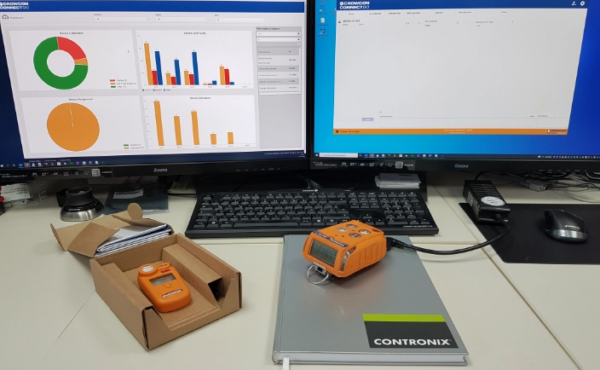

Bei der HF-Gasdetektion wird ein elektrochemischer Sensor verwendet, der anfällig für Interferenzen mit anderen Gasen ist (z. B. SO2 und NO2, die häufig in Motorabgasen vorkommen). Als Experten auf dem Gebiet der Gasdetektion arbeiteten die Crowcon-Mitarbeiter in der Entwurfs- und Planungsphase mit dem Benutzer zusammen, um sicherzustellen, dass die Detektoren an geeigneten Stellen platziert wurden, um mögliche Interferenzen durch andere Gase zu minimieren und gleichzeitig eine angemessene Abdeckung potenzieller Leckstellen zu gewährleisten. Der Aspekt der Wartung von Gasdetektoren ist von entscheidender Bedeutung, da monatliche Stoßprüfungen erforderlich sind. Die einzigartige Art und Weise, in der XgardIQ Bump-Tests vereinfacht und registriert, hat für zusätzliche Effizienz und Rückverfolgbarkeit der Aktivitäten gesorgt. Bei über 40 Geräten vor Ort ist eine einfache Wartung von entscheidender Bedeutung, um die Ausfallzeiten der Detektoren zu minimieren und die Zeit zu reduzieren, die das Personal in potenziell gefährlichen Bereichen verbringt.

Das Service-Support-Team von Crowcon wurde mit der Unterstützung der Raffinerie beauftragt, da es in diesen schwierigen Umgebungen effektiv arbeiten konnte.

Das erfolgreiche Ergebnis

Die Raffinerie hat für diese wichtige Anwendung erfolgreich die intelligenten Detektoren von Crowcon XgardIQ mit im laufenden Betrieb austauschbaren Sensoren eingesetzt. Der XgardIQ Detektor hat sich als robust und zuverlässig erwiesen. Vor allem aber ermöglichte die Hot-Swap-Sensor-Option dem Crowcon-Ingenieur, den Sensor außerhalb gefährlicher Umgebungen zu kalibrieren.

Seit der Inbetriebnahme sind mehr als drei Jahre vergangen, und bis heute gab es keine Berichte über Sensorabweichungen oder Detektorausfälle. Und mit der Serviceunterstützung von Crowcon vor Ort hat der Kunde die Gewissheit, dass diese wichtige Anforderung der Gasdetektion erfüllt wurde.

Kontaktieren Sie uns noch heute mit Ihren Anforderungen, um zu sehen, wie wir Ihnen helfen können!

Verwandte FALLSTUDIEN

Abonnieren Sie

, um die neuesten Erkenntnisse

in Ihrem Posteingang zu erhalten.

Lesen Sie über Crowcon's Datenschutz und Cookie-Richtlinie hier. Wenn Sie Ihre Meinung ändern, können Sie sich jederzeit abmelden