Für viele Heizungsinstallateure ist der Abgasanalysator/Verbrennungsanalysator ein unverzichtbares Gerät, so sehr, dass die meisten ohne ihn nicht arbeiten könnten. Für die Kalibrierung und Wartung muss der Techniker den Analysator jedoch in der Regel für eine gewisse Zeit wegschicken. Wenn der jährliche Kalibrierungstermin wieder einmal ansteht, ist mancher versucht, ihn aufzuschieben...

Bitte ignorieren Sie diese Versuchung. Es ist absolut unerlässlich, dass Sie Ihr Abgasanalysegerät jedes Jahr kalibrieren lassen, und wenn Sie das nicht tun, kann Sie das Ihren Job kosten - oder Schlimmeres. Eine rechtzeitige jährliche Kalibrierung ist einfach nicht verhandelbar, und in diesem Blogbeitrag gehen wir auf die Gründe dafür ein.

Jährliche Zertifizierung erforderlich

Ein Rauchgasanalysegerät ist eine Sicherheitsausrüstung, und seine Genauigkeit kann - im wahrsten Sinne des Wortes - eine Frage von Leben und Tod sein. Die Sensoren im Inneren Rauchgas Analysatoren reagieren mit den Gasen, die sie erkennen, und lassen mit der Zeit leicht nach. Zusammengestellt im Verlauf eines Jahren aktiven Nutzung, die Zersetzung kann zu Ungenauigkeiten in den Messwerten führen. Hinzu kommt, wie bei jedem Gerät können Dinge schief gehen und Teile ausfallen. Deshalb verlangen alle Hersteller von Abgasanalysegeräten ein jährliches Kalibrierungszertifikat, und die Folgen eines fehlenden Zertifikats können rechtlich, finanziell und persönlich katastrophal sein.

Stellen Sie sich zum Beispiel vor, dass sich ein Unfall ereignet hat und jemand oder etwas zu Schaden gekommen ist, weil Ihr Abgasanalysator ein Problem nicht erkannt hat. Wenn dieses Analysegerät nicht zertifiziert war und nicht innerhalb des vorgeschriebenen Zeitraums kalibriert wurde (was leicht festzustellen wäre, da auf den Gasberichten die entsprechenden Zeiten und Daten aufgedruckt sind), dann können Sie und/oder Ihr Arbeitgeber dafür straf- und zivilrechtlich haftbar gemacht werden, da Sie Ihre Sorgfaltspflicht gegenüber Ihrem Kunden nicht erfüllt haben.

Wenn Ihr Verbrennungsanalysegerät Anzeichen einer Störung aufweist oder die jährliche Kalibrierung fällig ist, müssen Sie es daher umgehend anmelden.

Wie sieht es mit den Kosten aus?

Manchmal sind Ingenieure versucht, die Kalibrierung aus Angst vor den Kosten aufzuschieben. Und ja, es können Kosten aufgrund von Schäden oder Verschleiß entstehen: aber welchen Preis zahlen Sie für die Sicherheit (sowohl für die Sicherheit der Menschen, denen Sie dienen, als auch für die Sicherheit Ihres eigenen Arbeitsplatzes oder Ihres Unternehmens)? Wenn Kosten ein Thema sind, gibt es vielleicht Möglichkeiten, diese zu verringern. Die Hersteller wissen, dass die Kalibrierung ein wiederkehrender Kostenfaktor ist, und einige bieten Vorauszahlungsoptionen an, um die Verwaltung dieser Kosten zu erleichtern. Wenn Sie nicht sicher sind, ob dies für Ihr Gerät zutrifft, lohnt es sich, mit dem Hersteller zu sprechen, denn die Einsparungen können erheblich sein.

Was passiert bei der Kalibrierung?

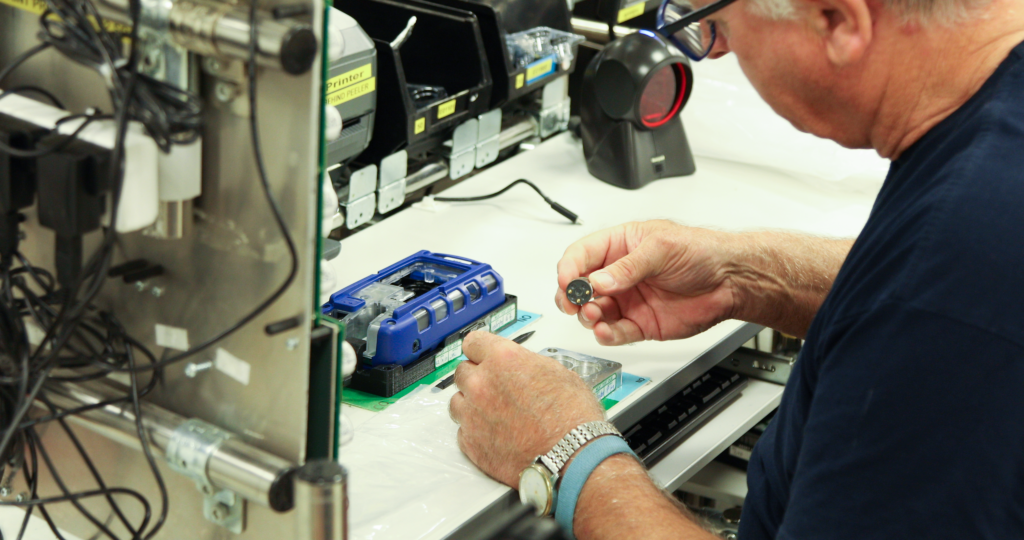

Bei der jährlichen Wartung und Kalibrierung wird Ihr Abgasanalysegerät überprüft und alle Komponenten (z. B. ein Sauerstoffsensor) werden bei Bedarf ausgetauscht. Eine bekannte KonzentrationKonzentration eines zertifizierten Prüfgases in den Analysator und tdas GerätSoftware des Geräts wird angepasst, um sicherzustellen, dass berücksichtigt abfallende Sensorreaktion zu berücksichtigen und sicherzustellen, dass das Analysator angemessen reagiert auf alle Gase im gesamten Erfassungsbereich reagiert.

Nicht abwarten - kalibrieren

Wie Sie sehen, sind die Kalibrierung und die damit verbundenen Änderungen für das Funktionieren Ihres Analysegeräts von entscheidender Bedeutung, so dass Sie die jährliche Kalibrierung niemals aufschieben oder übersehen sollten: Sie dürfen ein Abgasanalysegerät überhaupt nichtnicht mehr verwenden, wenn die letzte Kalibrierung abgelaufen ist. Dies gilt unabhängig davon, wie oft Sie das Gerät verwenden: Die Risiken sind dieselben.

Weitere Informationen finden Sie auf unserer speziellen HLK-Seite.

BRANCHENEINBLICKE

Abonnieren Sie

, um die neuesten Erkenntnisse

in Ihrem Posteingang zu erhalten.

Lesen Sie über Crowcon's Datenschutz und Cookie-Richtlinie hier. Wenn Sie Ihre Meinung ändern, können Sie sich jederzeit abmelden